Knockout Systems

Utilizing forward-thinking technology, Hyson™ INTELLImax Knockout Systems™ enable flexible, timed part knockout with customized force, controllability and ease of use.

With more force and more control, we have a solution to meet your knockout needs.

- Self-contained system delivers a flexible solution for part knockout applications.

- Active hydraulic system is ideal when more controllability is needed or when the press has reached it maximum force capacity.

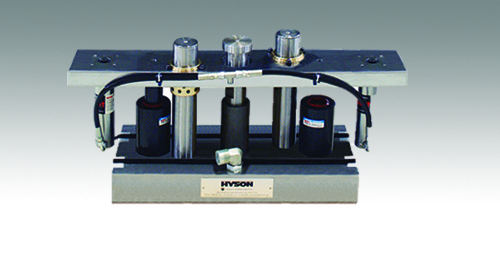

The self contained system

The self contained system operates without external hydraulics or other equipment and can be customized to your application.

- With the knockout mounted directly to the slide/ram face, the need to modify or manually adjust the system is eliminated

- An electric signal actuates the system and drives the press knockout bars at the user-determined time

- Force and timing are all under your control

- Ensures repeatability with correct timing

- Modular design allows for ease of installation, seviceability and interchangeability

The active hydraulic system

The active hydraulic system performs controlled Knockout without using press tonnage and pulls force from a compact power unit that acutates the knockout system.

- Enables fine-tuning anywhere within the press stroke

- Ability to start the system retracted in home position

- Can be implemented into upper and lower knockout operations

Ideal for:

- Applications where more control is needed or when the press has reached its maximum force capability

- AHSS and deep draw applications

- Applications requiring tranfer and automation

Preview

Teaming with Hyson

Gives metal stampers the tools and resources to:

- Eliminate die and press damage due to mechanical knockout failure

- Eliminate human error traditionally introduced during set up

- Custom engineer solutions speciific to their application

- Reduce installation and set-up time

- Increase press time

- Reduce scrap