High Speed Stamping Solutions

Our high speed stamping solutions are designed to help your stamping press to safely run at faster speeds reliably without affecting part quality and tool life-time.

Better Part Quality

Low-quality parts can be caused by overheating low-quality Gas Springs or fatigued Coil Springs. With our high-speed solutions, you can run at higher production outputs while being safer, more reliable, and not affecting part quality.

Extend Tool Lifetime

Running at high speeds enables faster production but can affect the tool's lifetime. Our solutions allow you to increase your output without adversely affecting your press, tool, or part quality.

Advanced Lubrication System | Dyne-a-lube

Dyne-a-lube is a patented lubrication system compatible with any of Hyson’s Nitrogen Cylinder Systems, designed to have them run at higher speeds and have longer life cycles.

High-Speed Stamping serves a wide variety of industries, including:

- Aerospace

- White Good Appliances

- Automotive

- Electric Vehicles (Battery Casing)

- Electrical Equipment

- Electronics

- Food and Beverage

- HVAC

- Medical

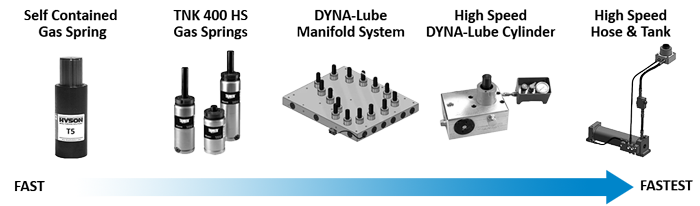

Solutions for High Speed Stamping

200+ Strokes Per Minute | 1. High Speed Hose & Tank

100-200+ Strokes Per Minute | 2. High Speed DYNE-A-Lube Cylinder

100+ Strokes Per Minute | 3. DYNE-A-Lube Manifold System

>100 Strokes Per Minute | 4. TNK 400 HS Gas Springs

>100 Strokes Per Minute | 5. Self Contained Gas Springs

Applications for High Speed Stamping:

- Ammunition

- EV (Electric Vehicle Battery Casing)

- Cans

- Cases

- Chains

- Closures

- Covers & Enclosures

- Cups

- Bracket

- Eyelets

- Ferrules

- Knobs

- Plates

- Rings

- & more

1. HIGH SPEED HOSE & TANK | 200+ SPM

- Maximum Stroke Available 6"

- Maximum Contact Force: 6 Tons

- Service life: 3+ million strokes

2. HIGH SPEED DYNE-A-LUBE CYLINDER | 100-200+ SPM

- Maximum 1" Stroke (For Short Stroke Applications)

- Maximum Contact Force: 6 Tons

- Service life: 3+ million strokes

3. DYNE-A-LUBE MANIFOLD SYSTEM | 100+ SPM

- Maximum 6" Stroke

- Maximum Contact Force Available: 6 Tons

- Service life: 2-3 million strokes

4. TNK 400 HS GAS SPRINGS | >100 SPM

- Maximum Stroke Available 3"

- Maximum Contact Force: 0.44 Tons

- Service life: 2+ million strokes

5. SELF CONTAINED GAS SPRINGS | >100 SPM

- Maximum Stroke Availability: 80mm

- Service life: 2 million strokes